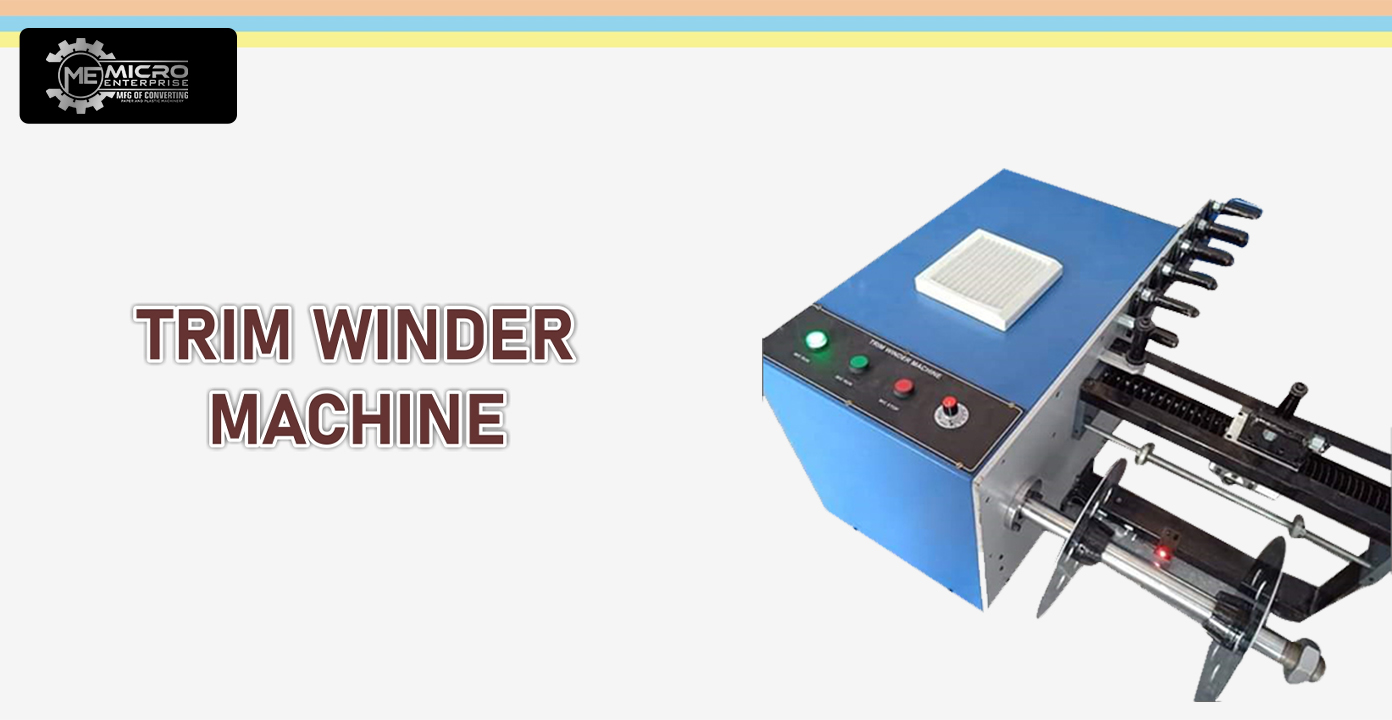

In modern manufacturing and packaging, efficiency and waste reduction are critical. The Trim Winder Machine is designed to efficiently collect and rewind trim waste generated during slitting, printing, and laminating processes. This machine ensures a clean, organized, and productive work environment while improving operational efficiency.

Micro Enterprise has established itself as a trusted global supplier of industrial machinery since 1998. With decades of experience, the company is renowned for offering high-quality, durable, and energy-efficient machines. The Trim Winder Machine is one such innovation, designed to meet the demands of modern production units.

By integrating this machine into your workflow, you can save time, reduce material wastage, and ensure consistent performance across all operations.

A Trim Winder Machine is an industrial solution that collects trim waste and rewinds it into organized rolls, making disposal or recycling seamless and efficient. It is primarily used in printing, packaging, laminating, and BOPP tape industries.

This machine handles various materials including paper, film, foil, plastic, and nonwoven fabrics, making it versatile for multiple industrial applications. It ensures that production areas remain uncluttered, enhancing safety and operational flow.

Understanding the functionality of a Trim Winder Machine allows businesses to streamline processes, reduce labor costs, and maintain high-quality output with precision winding.

The Trim Winder Machine is engineered with features that make it a standout in industrial operations.

These features make the Trim Winder Machine an essential tool for businesses seeking precision, efficiency, and reliability in their production processes.

| Type | Machine |

| Frame Material | Mild Steel |

| Material Type | Paper, Film, Plastic, Nonwoven |

| Motor Power | 1.5 KW To 5 KW |

| Drive Method | AC Motor With Gearbox |

| Machine Type | Trim Winder |

| Winding Capacity | Up To 500 Meters Per Minute |

| Display Type | Digital |

| Core Length | Adjustable From 200 Mm |

| Frequency | 50 - 60 Hz |

| Rewind Method | Surface Rewind |

| Machine Dimension (LxWxH) | Varies Based On Model |

| Used For | Winding Materials Like Plastic Films, Paper, And Foils |

| Rewind Direction | Bi-directional |

| Unwinding Mechanism | Pneumatic Or Electric Unwinding |

| Noise Level | Less 85 DB |

| Features | Easy To Use, Compact Design, Adjustable Roll Size, Energy- Efficient Etc |

| Exporter By | Micro Enterprise |

| Country Of Origin | India |

With these specifications, the Trim Winder Machine is built to deliver consistent, high-performance results suitable for demanding industrial environments.

Investing in a Trim Winder Machine offers numerous benefits to manufacturers and production units.

This combination of advantages positions the Trim Winder Machine as a cost-saving and productivity-enhancing solution for any production facility.

The versatility of the Trim Winder Machine allows it to be used across multiple industries.

Any industry that requires precision winding, clean workspaces, and efficient trim handling can benefit from implementing the Trim Winder Machine.

Choosing the right winding machine is critical for industrial efficiency. The Trim Winder Machine offers several advantages over standard winding solutions.

By comparing performance, energy usage, and durability, the Trim Winder Machine emerges as the superior choice for modern production environments.

Proper maintenance ensures long-term performance and reduces downtime. Key tips include:

Micro Enterprise provides guidance and support to help customers maintain peak machine performance, ensuring long-lasting industrial efficiency.

Micro Enterprise is a trusted name in industrial machinery, recognized for reliability and high-quality manufacturing solutions.

Choosing Micro Enterprise ensures that businesses invest in machines that deliver efficiency, precision, and long-term reliability.

Q1. What materials can the Trim Winder handle?

A1. It can efficiently wind paper, film, foil, plastic, and nonwoven materials.

Q2. What is the maximum winding speed?

A2. The machine supports speeds up to 500 meters per minute.

Q3. Is the machine energy-efficient?

A3. Yes, it features AC motors designed to reduce electricity consumption.

Q4. Is it suitable for bulk orders?

A4. Yes, wholesale pricing is available for businesses requiring multiple machines.

Q5. What after-sales support is provided?

A5. Micro Enterprise offers technical guidance, spare parts availability, and maintenance support for all machines.

The Trim Winder Machine is an indispensable solution for modern industrial operations, offering efficiency, precision, and cost savings. By reducing material waste, improving production speed, and maintaining consistent quality, it ensures businesses remain competitive and productive.

Micro Enterprise, with decades of expertise and a reputation for delivering high-quality industrial machinery, provides machines that are reliable, durable, and energy-efficient. Contact Micro Enterprise today to request a demo, quote, or bulk order and elevate your production operations to the next level.